Improving Lives Through Science

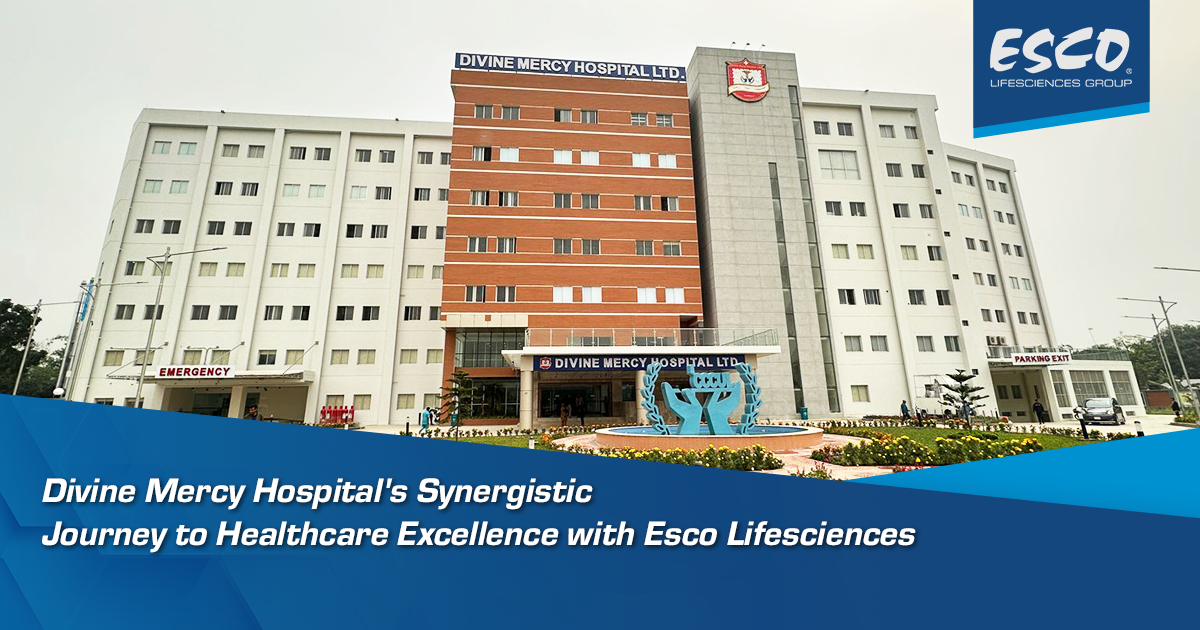

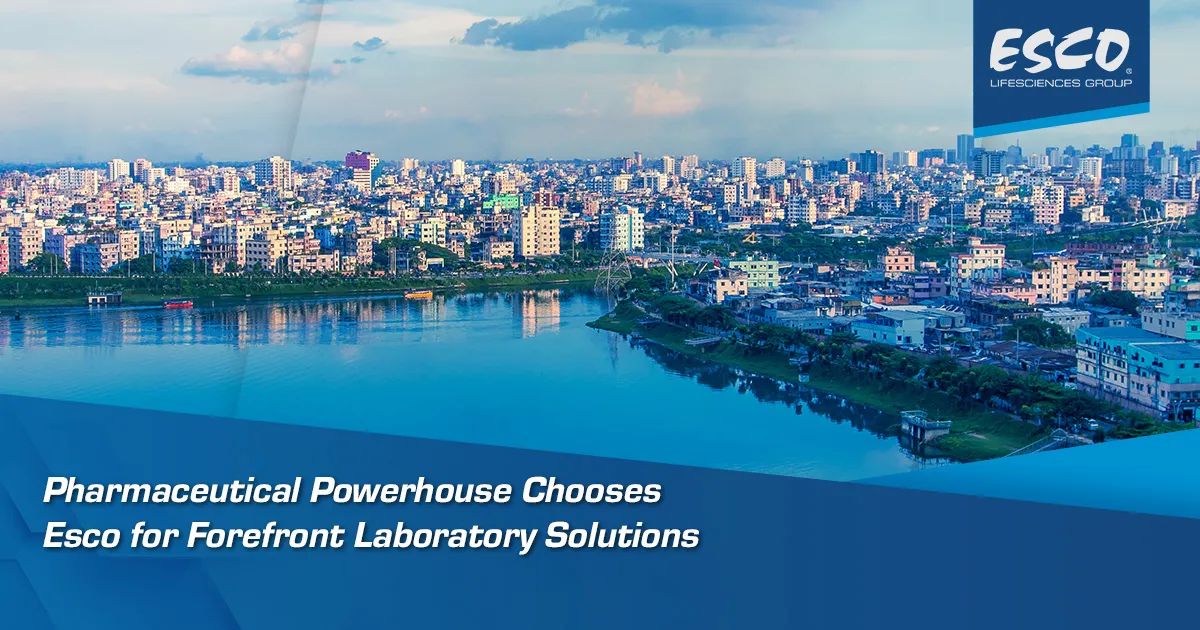

Esco Lifesciences is a world-leading life science company with a diversified portfolio and sales in over 100 countries. As a manufacturer of laboratory and biopharma equipment, and IVF medical devices, Esco offers tailored solutions that fit the needs of laboratories in various industries.

Esco Lifesciences contributes to meet the challenges of the 21st century with a diverse range of business units. The company continuously innovates its products to help the clinical and industrial laboratories achieve successful conclusions in research and development, quality control, and analysis. We continue to provide reliable world-class equipment to help pharmaceutical companies make their products safer and more cost-effective. And with the increasing demand of the IVF industry, we have developed efficient ART equipment to enable equitable access to infertility care.

Life Science Tools

Esco Lifesciences provide a one-stop solution from installation to decommissioning of your equipment!

Esco Lifesciences assures its customers of its products quality. Limited warranty policies cover material defects and workmanship.

As a world leader in clean air, containment and laboratory equipment technologies Esco Lifesciences offers training on the installation, certification, maintenance and servicing of its products.

Esco Aster, the CDMO of Esco Lifesciences, provides process development (PD) and contract manufacturing (from upstream to downstream, formulation and filling), consultation, clinical research services bridging the translation gap from bench to bedside.

1 %

1 Years

1 +

1